|

Posted on the official SNS for overseas of the Cabinet Office Prime Minister's official residence |

|

【Facebook】

【Twitter】

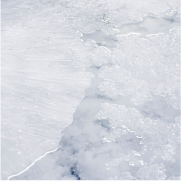

In the southernmost tip of the Izu Islands, which are a part of Tokyo City, lies Aogashima island.

|

About the manufacturing method. |

Hingya salt made using the power of a volcano

Hingya salt is made in cooperation between humans and Earth’s natural energy.

1. Seawater drawing

Seawater from the Kuroshio Current of the Pacific

2. Pouring the seawater into pans

The only heat source used is geothermal steam. The water temperature is approx. 60℃.

3. Crystallization

13 days following the pouring of the seawater into the pans

4. Removal from pans

6 days after crystallization

5. Dewatering

Bittern is removed using a centrifuge.

6. Drying

Here, too, only geothermal steam only is used for four days.

7. Griding

Large crystals are ground.

8. Checking for impurities

Repeatedly stirring and turning the salt, small stones and wooden particles are removed.

9. Packaging

All salt is hand packed.

10. Inspection

Tapping is used to thoroughly check whether every bag is sealed.

11. Labelling

The products are finished by carefully attaching labels to them.

Our clients |

|

Yamashita Co,Ltd. (uses Hingya bittern)

|

|

|

|

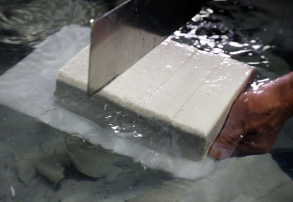

I remember that I found Hingya’s bittern reacts well with soy milk and that it made the coagulation process smooth.

Eventually, Hingya started producing bittern so dense it was unmeasurable with a Baumé meter. The denser bittern gets, the quicker it reacts, moving its handling beyond a tofu maker’s common practice. That was around the time when they became a private enterprise.

I discovered that this density, which could easily be dismissed as a disadvantage, could really be turned into an advantage. Out of flavour and mechanical structure, the two components that decide whether tofu becomes tasty, it promotes the latter. It enables you to play around by gently synthesizing and combining smooth lumps of various sizes.

This bittern brims with minerals from the middle of the wild Kuroshio Current. It is made with a low-temperature heating procedure using volcanic fumes, requiring no firewood, electricity or gas. It is the ultimate sustainable procedure.

You can’t help but be charmed by this beautiful seawater’s blessing.

|

Koyama Sushi Restaurant (uses Hingya salt) Closed at the end of December 2022

|

|

|

|

|

Koyama Sushi Restaurant (uses Hingya salt) To avoid food from spoiling, I believe it is good for salt to ripen food more quickly, even if only by a minute of a second. Furthermore, in the case of seafood, applying salt coagulates liquid proteins and condenses the food’s umami flavour. I feel that Hingya salt is strong at performing both functions. |

Products |

商品写真:三木匡宏

If you are interested in Hingya salt

We have made it possible to make salt with flavourless and odourless geothermal steam.

Large amounts of calcium and magnesium are what set Hingya salt apart.

Because making salt with geothermal steam takes effort and time, we are not capable of large-scale production.

However, salt made with the forces of nature has a taste that brings you close to the actual sea.

| ① 50g ‥‥ 260yen ② 100g ‥‥ 520yen ③ 200g ‥‥ 1,030yen ④ 1kg ‥‥ 4,500yen |

| 300ml ‥‥ 480yen |

| 10 l ‥‥ 5,770yen |

| (this autumn, we are planning to start selling 300 ml bottles again) |

Aogashima Salt Works Co.,Ltd

〒100-1701 Aogashima Village,Tokyo,Japan TEL:04996-9-0241